Increasing Efficiency in Complex Agricultural Process

Our client is the global leader in the agricultural industry for creating sustainable flowers. Their Material Creation process is lengthy and complex due to many variables. To bring transparency into the said process, we started by connecting two different processes that rely on each other throughout the creation of new flowers. Subsequently, we gave our customer the data to understand the effort for the material creation versus the actual usage of the material. In addition, by defining an optimal path, we could detect process-related anomalies, the desired time to market and the impact of undesired activities. Our client now makes objective decisions based on data and have a thorough understanding of the actual situation of the Material Creation process.

tags

date

06 Jul 2022Our client is the global leader in the agricultural industry for creating sustainable flowers. They experiment extensively to develop new materials. Their Material Creation process is lengthy and complex due to many variables. To bring transparency into the said process, we started by connecting two different processes that rely on each other throughout the creation of new flowers. With complete transparency into the overall process, we gave our customer the data to understand the effort for the material creation versus the actual usage of the material. In addition, by defining an optimal path, we could detect process-related anomalies, the desired time to market and the impact of undesired activities.

All in all, the process now has complete transparency, and we gave our customer the tools to regulate and manage said process pro-actively. Now, they make objective decisions based on data and have a thorough understanding of the actual situation of the Material Creation process.

Intro

One of our clients is a company in the agriculture industry who came to us to create clarity for a very complex process. They are global leader in this industry, with an expertise in sustainable flower production due to their extensive knowledge of genetics and breeding. Founded over 20 years ago, they have offices spread out over the globe and have close to 50,000 employees.

Challenges

One of their core businesses is the creation of new material. This creation requires the underlying data to be complete and up-to-date. When the client came to us, this was not the case. The lengthy process exists of multiple phases such as breeding, testing and producing.

To create materials, varieties are needed due to having to experiment. These combined processes provide the complete overview that require visibility. As such, this is a complex process with many different aspects to it.

Our client wanted to get more insights and clarity into the complete Material Creation Process and decided that focusing on preventing manual work regarding name changes of materials would be the first step to streamlining this process.

They want to measure effort for the material creation versus the actual usage of the material. This project gave them an opportunity to increase transparency and to understand the sequence of activities.

Solutions

Complete Process Transparency

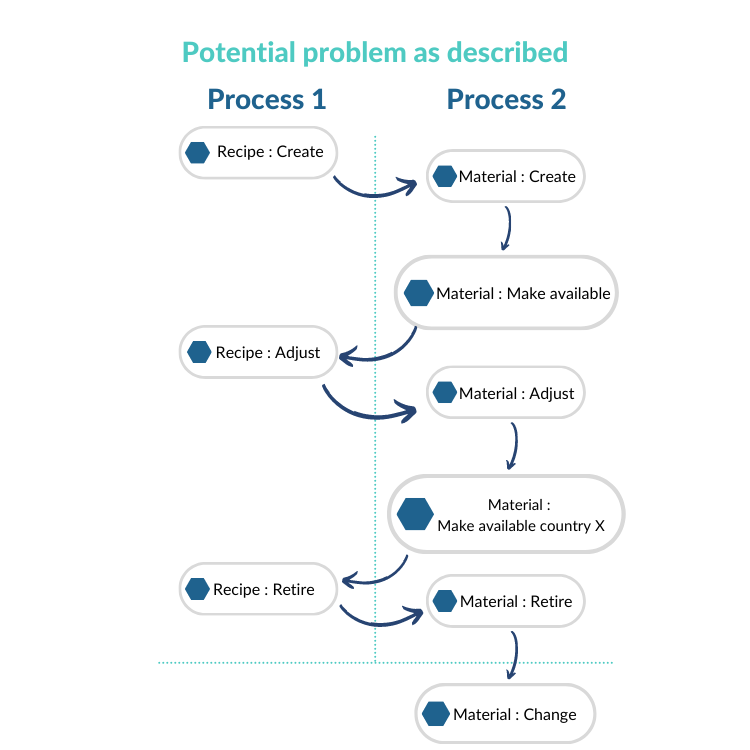

We started off with creating a digital twin of the Material Creation process. As materials based on one or multiple formulas, a multi event log was needed. That entails that two different processes had to be connected. This process connection enabled us to link the formula of materials to the actual creation of said end product.

Conformance

Through the newly created process transparency, together with the customer, we defined an optimal path. This optimal path helped us to detect process related anomalies, the desired time to market and the impact of undesired activities. As such, we have our customer the tools to streamline and actively optimize said process. Process related anomalies were for instance, certain changes to a material even though this material is not of use any longer and officially taken off the market.

Outcomes

Due to our efforts, not only did the customer gain full transparency into their process, they gained control over it. With these insights into their process, they have a much better handle on the entire situation and can anticipate much better on the complex variables within the process. Overall, the process is more streamlined and is working optimally. With this project, the client understood the value of process mining and decided to implement it further. Through setting up a Centre of Excellence, Apolix is now working together with the client to establish process mining throughout the entire company and to educate their employees on how to gain deeper insight into their processes.

Do you believe that you are not maximizing the ROI you can get out of your information system? As Process Mining specialists, we can help you uncover the truth in your system.