tags

date

01 Oct 2024Summary

Calor Gas Ltd. is the UK’s leading supplier of LPG and sustainable alternatives. For over 85 years they have been supplying rural Britain with energy to keep their homes and businesses running.

Following a major systems migration, Calor developed a partial backlog of unbilled orders, resulting in delayed cash flow and customer frustration. Apolix revealed the extent and root causes of the problem and implemented the Shipped Not Invoiced app from Celonis. By using the app to identify and tackle high-priority orders, the backlog was reduced by 30% in just two months, significantly accelerating cash flow.

Apolix and Calor Gas are now exploring process mining use cases across the entire order-to-cash process, as well as source-to-pay, accounts receivable and install-to-maintain.

Key takeaways

- Apolix revealed multiple billing blocks causing an invoicing backlog

- Together, Apolix and Calor Gas cut unbilled orders by 30% in two months

- This reduction had a rapid and significant impact on cash flow

- Calor Gas and Apolix are expanding process mining to other core processes

Calor Gas

Over the past 85 years, Calor have expanded quickly to meet evolving needs and reach more customers. Every stage of their history has been marked with innovation and new ideas. Apolix is proud to be apart of that journey and to help bring transparency to processes in every part of the business.

The company has been on a transformation journey that included replacing JD Edwards with SAP S/4HANA. In 2023, around the time of the go-live, the team at Calor – led by Head of Process Excellence, Kam Gakhal – began working with Apolix to explore opportunities to make the organisation more data driven. The organisation wanted to proactively use process mining to drive continuous improvement.

“The relationship with Apolix has been really strong. Even though they’re not a local company, their team has been on site on a number of occasions. They’re a real partner for our business.”

– Kam Gakhal, Head of Process Excellence, Calor Gas Ltd.

The challenge

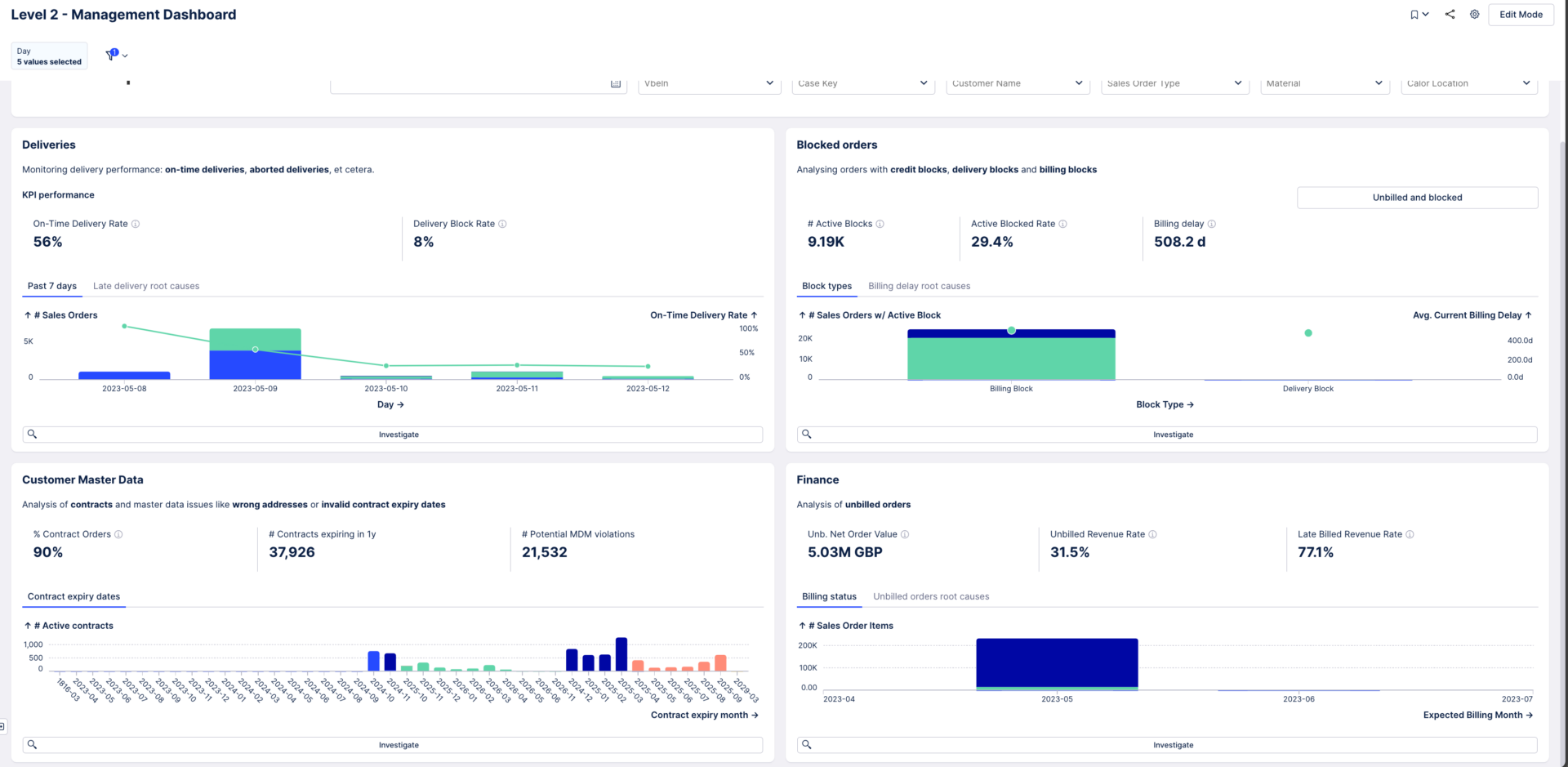

Following the SAP go-live, Calor became aware of issues in the order-to-cash process, specifically within the invoicing cycle. Calor’s invoicing process is relatively complex due to rules around taxation and climate change levies. They discovered some customisations within the invoicing processes weren’t functioning as intended.

Calor soon realised there were invoicing delays, with a backlog of orders that had been shipped but not billed. But they had limited visibility into the scope of the problem.

These delays were impacting cash flow. They were also frustrating for customers, and for the company, which strives to deliver exceptional customer service. To ensure invoices were issued in line with customer expectations, and improve cash flow into the business, Calor needed to gain full visibility into the order-to-cash process, identify the root causes of billing delays, and reduce the backlog.

“We needed to make sure we were doing everything we could to invoice customers in a timely way, getting invoices issued promptly and in an accurate manner coupled with getting cash into the business at the right time.”

Solution: Process mining

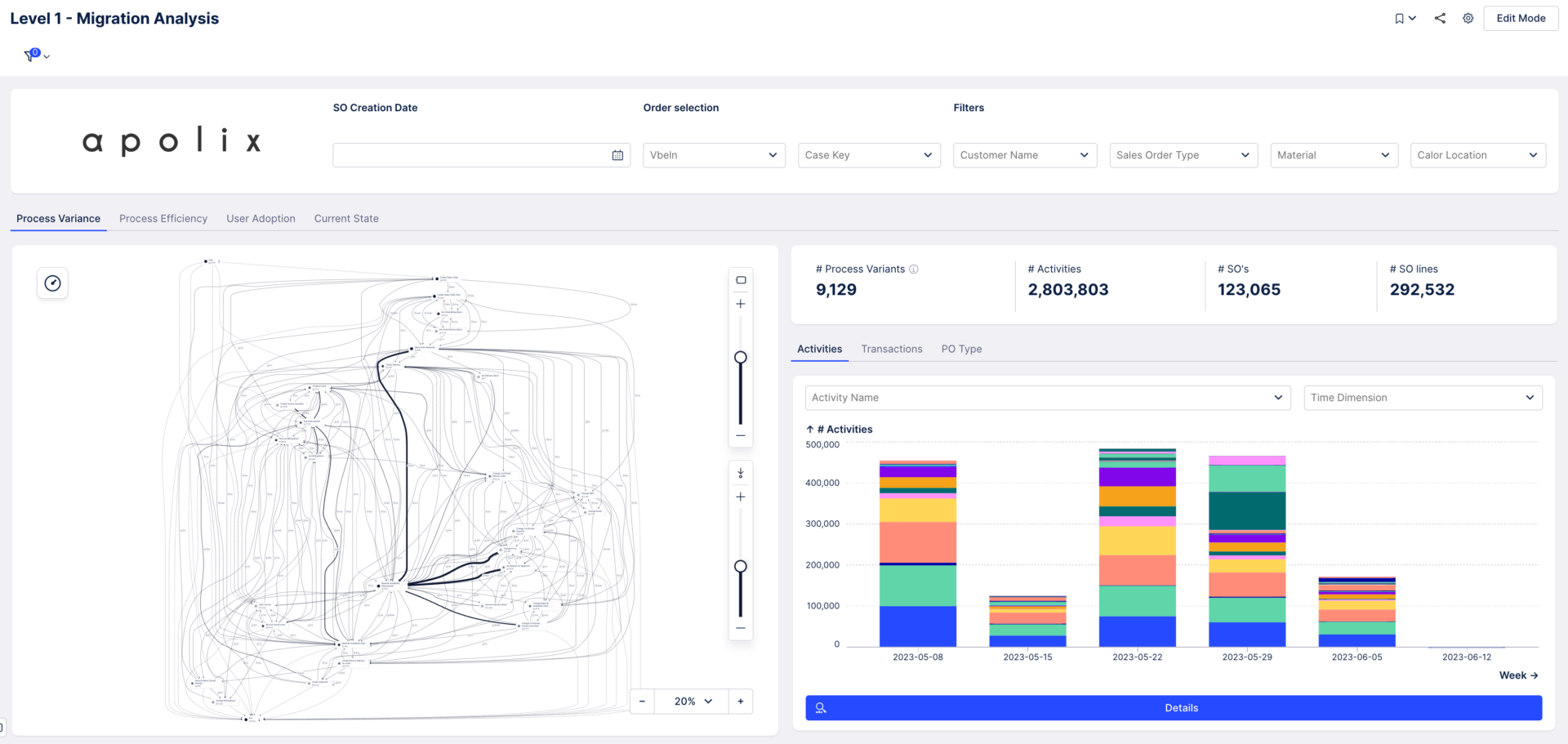

Using process mining, Apolix revealed the extent of the backlog and identified the points in the process where sales orders were getting stuck. There wasn’t a single root cause preventing Calor from invoicing shipped orders on time. Instead, a variety of billing blocks were identified, ranging from incomplete or inaccurate sales order information to issues in the reconciliation phase after deliveries were made.

“With process mining we can exactly identify in which part of the process sales orders are stuck. Therefore, we were able to exactly identify which sales orders were shipped, but not invoiced and also what corrective action was required to enable invoicing to occur.”

– Victoria Walsh, Finance Process Lead, Calor Gas Ltd.

Apolix implemented the Shipped Not Invoiced app from Celonis to identify orders that had been delivered but not billed, and understand the root cause of each delay.

The app provides the flexibility to prioritise orders based on factors such as age, order value, or product, and to alert teams to issues with critical customers.

Outcome: Rapidly reduced backlog

By implementing the app, Apolix helped Calor Gas to tackle unbilled orders according to priority. With real-time insight into billing delays, and an understanding of the causes, the app pushes actionable insights out to the business so they can be addressed.

The backlog of unbilled orders reduced by 30% in just two months, causing a significant financial impact.

The partnership between Apolix and Calor includes focusing on training and change management in areas where issues are identified. the app to the unique needs of the business ensure the best outcomes.

“We meet with Apolix multiple times a month to check in on what’s happening and what developments are needed as new requirements continue to emerge. We didn’t just end up with a suite of reports and that was it – our needs have evolved and our relationship with Apolix has evolved too.” – Kam Gakhal

Looking ahead: Bright future

Calor Gas is now working with Apolix to improve process performance both upstream, to address issues that occur before orders are shipped, and downstream in accounts receivable. What’s more, process mining is being used to improve other core business processes such as source-to-pay and install-to-maintain.

Moving on from initial high-level analyses with the process team, process mining is being rolled out to other business areas, with Apolix building operational dashboards that allow business users to self-serve.

“With Apolix’s help, we’re looking to push process mining out to the wider business now we have confidence in its ease of use and the information it’s presenting. It’s a super easy, intuitive tool.”

Want to learn more about Calor’s successful transformation journey? Watch our webinar below.